Core Facilities

Access core facilities

Core research facilities are research equipment and infrastructure that are available at a daily, hourly, or per-unit rate, for use by companies who contract with UMassD for use. Various levels of faculty or technician support is available, depending on the company’s internal expertise. Small Massachusetts-based businesses (<50 FTEs) can access core facilities at a reduced rate through the Massachusetts Innovation Voucher Program. Research facilities at UMassD that are officially recognized as core facilities include the following:

Bruker D8 Venture X-Ray Diffraction Facility

Core Director - David Manke | dmanke@umassd.edu

State-of-the-art dual source Bruker D8 Venture single-crystal diffraction system. Services include crystallization, data collection and structure determination. For more information please visit the X-Ray Diffraction Facility.

Bruker D8 ADVANCE X-Ray Diffraction Facility

Core Director - Patrick Cappillino | Email: pcappillino@umassd.edu Phone: 508-999-9167

Core Facilities Manager and Research Support - Yaping Liu | Email: yaping.liu@umassd.edu Phone: 508-910-6132

The Bruker D8 ADVANCE with DAVINCI is a state-of-the-art X-Ray powder diffraction system designed for ease of use, operation safety, and analytical versatility. Its modular hardware and intelligent beam components enable automatic, tool-free geometry switching with minimal user intervention. The system is powered by DIFFRAC.SUITE software, offering intuitive control, component auto-recognition, and advanced data analysis tools.

It is also equipped with an Anton Paar BTS 500 Heated Stage and an Electrochemical Cell for in-situ X-Ray transmission and reflection measurements under applied load. Bruker's Best-Data-Guarantee ensures consistent high-quality results.

Key Features

Automatic Geometry Switching: Tool-free, software-driven switching between diffraction geometries (Bragg-Brentano, parallel-beam, etc.) for diverse sample types.

Plug’n Play Beam Path Components: Intelligent component recognition and configuration ensure effortless hardware integration.

High-Precision Measurement: Delivers high-resolution powder diffraction data with guaranteed alignment and detection accuracy.

DIFFRAC.SUITE Software: Customizable GUI with advanced analysis algorithms for ease of use and data reliability.

In-Situ Measurement Capabilities: Equipped with BTS 500 Heated Stage and Electrochemical Cell for dynamic, real-time analysis under thermal and electrochemical stimuli.

Best-Data-Guarantee: Ensures top-tier data quality through factory-calibrated alignment and certified detector performance.

Laser Confocal Microscopy

Core Director - Maolin Guo | mguo@umassd.edu

The Zeiss LSM 710 confocal microscope system can collect transmitted light images (bright field and DIC) as well as conventional and confocal fluorescence images. Four lasers are available covering the 405 nm to 633 nm range.

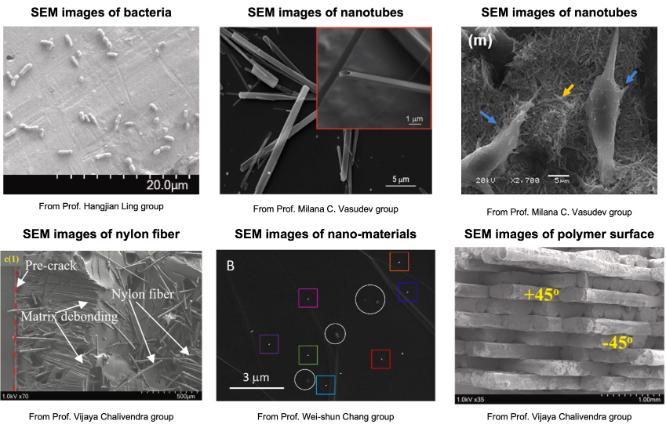

Scanning Electron Microscope Facility

The Hitachi SU-5000 field emission SEM is a microscope used to observe micron/nano-scale structures (resolution of 0.5 nanometer (10-9 m)). The FESEM is equipped with a deceleration mode for improved imaging and avoiding the effects of charging. The SEM is equipped with a secondary electron detector, backscatter detector and an additional STEM detector.

The Hitachi SU-5000 field emission SEM is a microscope used to observe micron/nano-scale structures (resolution of 0.5 nanometer (10-9 m)). The FESEM is equipped with a deceleration mode for improved imaging and avoiding the effects of charging. The SEM is equipped with a secondary electron detector, backscatter detector and an additional STEM detector.

Feature

- User friendly interface, EM Wizard and auto-calibration

- Large draw-out specimen chamber to accommodate larger specimens

Application Examples

Rate Price

|

Category |

Self |

Staff training or service |

Director training or service |

|

Internal rates |

$ 17.50/hr (billed in 15-minute increments) |

- |

- |

|

External rates |

$ 150/hr |

$ 250/hr |

$ 300/hr |

Contact

Core Director – Milana Vasudev | Email: milana.vasudev@umassd.edu Phone: 508-999-9284

Core Manager – Dapeng Li | Email: dli@umassd.edu Phone: 508-910-6872

Location

TEX003A (Basement of Textile Building)

SMAST Optic and Acoustic Test Tank

Core Director - Kyle Cassidy | Email: kcassidy@umassd.edu Phone: 508-999-8925

Core Facilities Manager and Research Support - Yaping Liu | Email: yaping.liu@umassd.edu Phone: 508-910-6132

90,000 – gallon acoustic – optic test tank designed for development and testing of underwater measurement concepts and devices. For more information please click Optic and Acoustic Test Tank.

SMAST Seawater Facility

Core Director - Kyle Cassidy | Email: kcassidy@umassd.edu Phone: 508-999-8925

Core Facilities Manager and Research Support - Yaping Liu | Email: yaping.liu@umassd.edu Phone: 508-910-6132

SMAST West Seawater Lab

The 2,200-square-feet, SMAST West Seawater Lab contains temperature-controlled rooms for long-term behavioral and physiological experiments and acclimation of marine organisms for culture and reproduction as well as a docking pier extend into Clark's Cove.

SMAST East Seawater Lab

The 6,000-square-feet, SMAST East Seawater Lab is designed to allow scientists the ability to conduct multiple experiments simultaneously and is configured with the flexibility to accommodate faculty members' research needs.

SMAST Biodegradability Laboratory Facility

Core Manager - Christopher Ward | Email: cward8@umassd.edu Phone: 508-910-6327

Core Facilities Manager and Research Support - Yaping Liu | Email: yaping.liu@umassd.edu Phone: 508-910-6132

The Biodegradability Laboratory at SMAST is a state-of-the-art research and product development facility. Opened in 2022, the Biodegradability Lab is designed to study the biological breakdown of plastic in natural environments, and provided businesses with a space to test sustainable products and materials.

Nuclear Magnetic Resonance Spectroscopy Facility

Core Director – Maolin Guo | Email: mguo@umassd.edu Phone: 508-999-8871

Core Facilities Manager and Research Support – Yaping Liu | Email: yaping.liu@umassd.edu Phone: 508-910-6132

The 400 MHz Nuclear Magnetic Resonance (NMR) spectrometer at UMass Dartmouth, a Bruker AVANCE III model funded by a $339,000 National Science Foundation (NSF) grant, is a vital research tool for the Department of Chemistry and Biochemistry. It enables students and faculty to perform in-depth chemical analysis, providing high-resolution data for structural characterization of molecules. The instrument supports a range of experiments, including 1D (1H, 13C, 19F, 31P) and 2D (COSY, HSQC, HMBC, NOESY, ROESY) experiments, as well as temperature-controlled and kinetic studies. This powerful spectrometer plays a key role in advancing research in chemistry and biochemistry while offering valuable hands-on training for students, bridging both educational and cutting-edge scientific research applications.

J-1500 CD Circular Dichroism Spectrometer

Core Director – Wei-shun Chang | Email: wchang2@umassd.edu Phone: 508-999-8247

Overview

The J-1500 CD spectrometer is a cutting-edge instrument designed to measure the differential absorbance of left- and right-circularly polarized light by chiral molecules in solution. This technique provides critical insights into molecule structure and conformational changes, making it especially valuable in drug development as well as in studies of proteins, nucleic acids, and small molecules.

Key Features

- Simultaneous measurement of circular dichroism (CD), linear dichroism (LD) and absorbance at 163-1600 nm.

- Measurement of CD, LD, absorbance, and reflection signal of powder samples with integrating sphere accessory.

- Automation titration system for precise sample addition while maintaining constant volume.

- Peltier temperature control ranging from -30 °C to 130 °C.

- Multiple data acquisition modes including wavelength scans, temperature scans, and fixed wavelength time scans.

- Fast scan speeds up to 10,000 nm/min for rapid data collection.

- Low noise levels and minimal stray light for sensitive measurements.

- Non-destructive analysis with 1 cm, 1 mm, and 0.1 mm cuvette options.

Applications

- Drug Development: Detailed analysis of stereochemistry in chiral drugs, monitoring ligand-induced conformational changes, and identifying binding sites critical for drug efficacy

- Protein folding and structural analysis, including secondary structure estimation and stability studies

- Purity assessment of optically active compounds

- DNA/RNA interaction and conformational studies

- Enzyme kinetics investigations

- Chirality measurement for inorganic compounds and crystals.

External Industry Rates:

- Unassisted: $40/hour

- Assisted: $80/hour

- Training: $100/hour

Hydraulic Materials Testing and Digital Image Correlation Systems

Core Director - Vijaya Chalivendra | Email: vchalivendra@umassd.edu Phone: 508-910-6572

Core Facilities Manager and Research Support - Yaping Liu | Email: yaping.liu@umassd.edu Phone: 508-910-6132

The Instron Hydraulic Materials Testing Device (a) with Digital Image Correlation (DIC) (b) facility enables comprehensive evaluation of material behavior under static, cyclic, and fatigue loading. Equipped with a 100 kN load cell and a double-acting servohydraulic actuator, the Instron system supports testing of a wide range of materials - including plastics, metals, composites, and ceramics. The integrated 3D Digital Image Correlation (DIC) technology provides full-field deformation measurements, enabling detailed analysis of failure mechanisms. This system significantly expands testing capabilities beyond existing lab equipment, which is limited to static testing of low-strength materials.

The Instron Hydraulic Materials Testing Device (a) with Digital Image Correlation (DIC) (b) facility enables comprehensive evaluation of material behavior under static, cyclic, and fatigue loading. Equipped with a 100 kN load cell and a double-acting servohydraulic actuator, the Instron system supports testing of a wide range of materials - including plastics, metals, composites, and ceramics. The integrated 3D Digital Image Correlation (DIC) technology provides full-field deformation measurements, enabling detailed analysis of failure mechanisms. This system significantly expands testing capabilities beyond existing lab equipment, which is limited to static testing of low-strength materials.

Atomic Force Microscopy

Core Director - Vijaya Chalivendra | Email: vchalivendra@umassd.edu Phone: 508-910-6572

Core Facilities Manager and Research Support - Yaping Liu | Email: yaping.liu@umassd.edu Phone: 508-910-6132

The Atomic Force Microscopy (AFM) system at UMass Dartmouth, supplied by Park Systems, is a high-resolution imaging and nanomechanical analysis platform designed to support interdisciplinary research in materials science, chemistry, biology, and engineering. This advanced instrument is a powerful tool for both research and education, providing students and faculty with hands-on experience in nanoscale characterization while enabling sophisticated experimental investigations across diverse scientific fields.

The Atomic Force Microscopy (AFM) system at UMass Dartmouth, supplied by Park Systems, is a high-resolution imaging and nanomechanical analysis platform designed to support interdisciplinary research in materials science, chemistry, biology, and engineering. This advanced instrument is a powerful tool for both research and education, providing students and faculty with hands-on experience in nanoscale characterization while enabling sophisticated experimental investigations across diverse scientific fields.

Key Features:

Multiple Imaging Modes: Consists of non-contact, contact, and current-sensing (conductive) modes for versatile surface analysis.

High-Resolution Topography: Delivers 2D and 3D imaging of surfaces with nanometer precision for metals, polymers, and biological samples—including live cells and tissues in liquid environments.

Nanomechanical Testing: Performs nanoindentation on soft and biological materials to determine Young’s modulus and hardness at the nanoscale.

Current–Voltage Characterization: Measures local I–V curves and current transport properties on conductive surfaces with high spatial resolution.

Advanced Image Analysis: Provides quantitative surface roughness measurements and detailed visualization using integrated software tools.

UltiMaker S5 FDM 3D Printer

Core Director - Vijaya Chalivendra | Email: vchalivendra@umassd.edu Phone: 508-910-6572

Core Facilities Manager and Research Support - Yaping Liu | Email: yaping.liu@umassd.edu Phone: 508-910-6132

The UltiMaker S5 is a professional-grade Fusion Deposition Modeling (FDM) 3D printer offering a large build volume of 330 x 240 x 300 mm (13 x 9.5 x 11.8 inches) and dual extrusion capabilities. It supports a wide range of materials including PLA, Tough PLA, Nylon, ABS, CPE, Polycarbonate, TPU, Polypropylene, and PVA, allowing for multi-material and soluble support printing. With its user-friendly interface and reliable performance, it is suitable for various applications from prototyping to production in industries such as aerospace, automotive, healthcare, and manufacturing.

Key Highlights:

- Large build capacity for complex and sizeable parts

- Dual extrusion for advanced multi-material and soluble support printing

- Extensive material compatibility for diverse project needs

- Streamlined user interface with advanced connectivity options

- Trusted solution for rapid prototyping to small-scale production

BMF MicroArch S140 3D Printer

Core Director - Mohammad Karim | Email: mkarim@umassd.edu Phone: 508-999-8434

Core Facilities Manager and Research Support - Yaping Liu | Email: yaping.liu@umassd.edu Phone: 508-910-6132

The BMF (Boston MicroFab) MicroArch S140 is an advanced 3D printer designed for ultra-high precision microfabrication. Utilizing Projection Micro Stereolithography (PµSL) technology, it achieves an exceptional resolution down to 10 micrometers, far surpassing most other 3D printing methods. This printer is ideal for applications requiring microscopic detail, such as microfluidics, biomedical devices, MEMS (Micro-Electro-Mechanical Systems), micro-optics, and the miniaturization of sensors and microelectronics.

Key Highlights:

- Ultra-high resolution printing with 10-micron precision

- Ideal for microfluidics, biomedical, MEMS, and micro-optical applications

- Uses Projection Micro Stereolithography (PµSL) for complex micro-scale geometries

- Capable of continuous multi-day print jobs for complex functional parts

Micro/Nano Fabrication and Thin Film Deposition Facility

Overview

This facility integrates the ElveFlow Photolithography System and the Kurt J. Lesker PVD 75 Thermal Evaporator, providing a complete workflow for microstructure fabrication and thin film deposition without the need for a clean room. It supports research in microfluidics, nanofabrication, thin-film electronics, surface engineering, plasmonics, and catalysis, offering precision from micron-scale patterning to sub-nanometer film growth.

ElveFlow Photolithography System

Core Director - Hangjian Ling | Email: hling1@umassd.edu Phone: 508-999-8540

Core Facilities Manager and Research Support - Yaping Liu | Email: yaping.liu@umassd.edu Phone: 508-910-6132

This facility is user-friendly for those new to microfluidics and microfabrication. It includes a spin coater for uniform photoresist layers from 1 to 250 µm; a programmable hot plate with uniform temperature; a UV lamp supporting samples up to 4 inches, featuring automated chuck movement and adjustable mask-to-substrate distance; and a tabletop desiccator, oven, and ultrasonic bath optimized for degassing, curing, and cleaning PDMS chips. The plasma cleaner kit, equipped with a pressure controller and pump, enables efficient PDMS-to-glass bonding.

Key Features:

- High-resolution up to 2 µm precision and controlled photoresist thickness from 1 to 250 µm

- Compatible with large sample size up to 4 inches in diameter

- No cleanroom required

- Ideal for microfluidics and microfabrication

Kurt J. Lesker PVD 75 Thermal Evaporator

Core Director - Wei-Shun Chang | Email: wchang2@umassd.edu Phone: 508-999-8247

Core Facilities Manager and Research Support - Yaping Liu | Email: yaping.liu@umassd.edu Phone: 508-910-6132

This high-vacuum physical vapor deposition (PVD) system produces uniform, high-purity thin films on solid substrates with precise thickness control from sub-nanometer to microns.

Key Features:

- High-vacuum thermal evaporation: 10⁻⁶–10⁻⁷ Torr operation

- Two thermal sources for sequential or co-deposition of different materials

- Wide material compatibility: Au, Ag, Cr, Ti, Pt, Pd, and more

- Substrate capacity: up to 150 mm (6 inches) in diameter with substrate rotation for uniform films

- Quartz Crystal Microbalance (QCM) for real-time deposition rate and thickness monitoring

- Automated process control with recipe programming for reproducibility

- Enables multilayer films, alloys, and heterostructures

- Ideal for plasmonics, thin-film electronics, catalysis, and nanofabrication

Develop a prototype or prove a concept

Our Center for Innovation and Entrepreneurship has laboratory and fabrication facilities designed to make your product or idea a reality.